Merdec One Only Chain Scrapers

Chain & Flight type Sludge and Scum Collectors

Merdec

With over 30 years’ experience in chain and flight collector systems design and manufacturing has given us a solid base to bring a new updated system to the market. During the designing of this system, Merdec has carefully taken into account all the most important factors for the benefit of the customer.

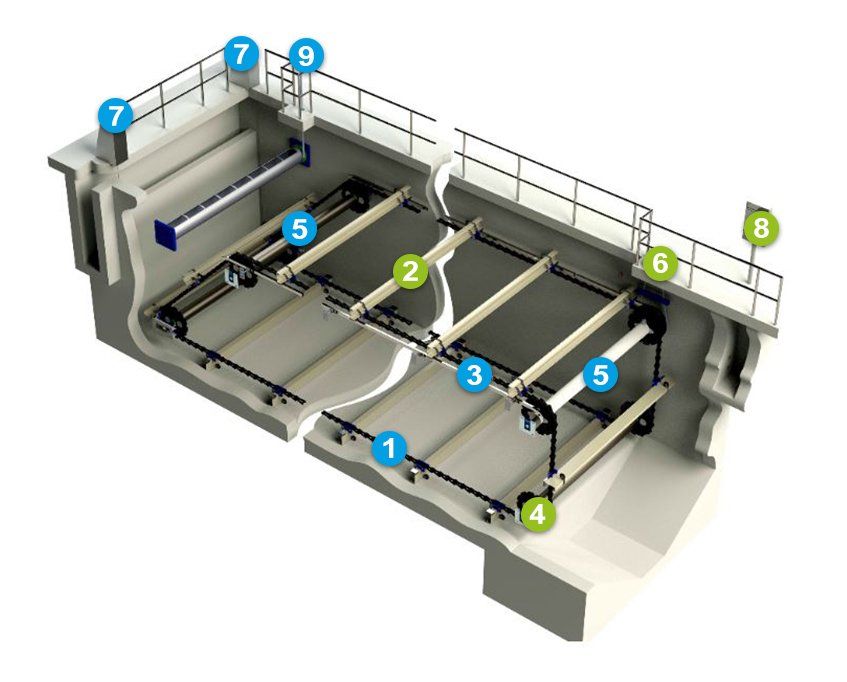

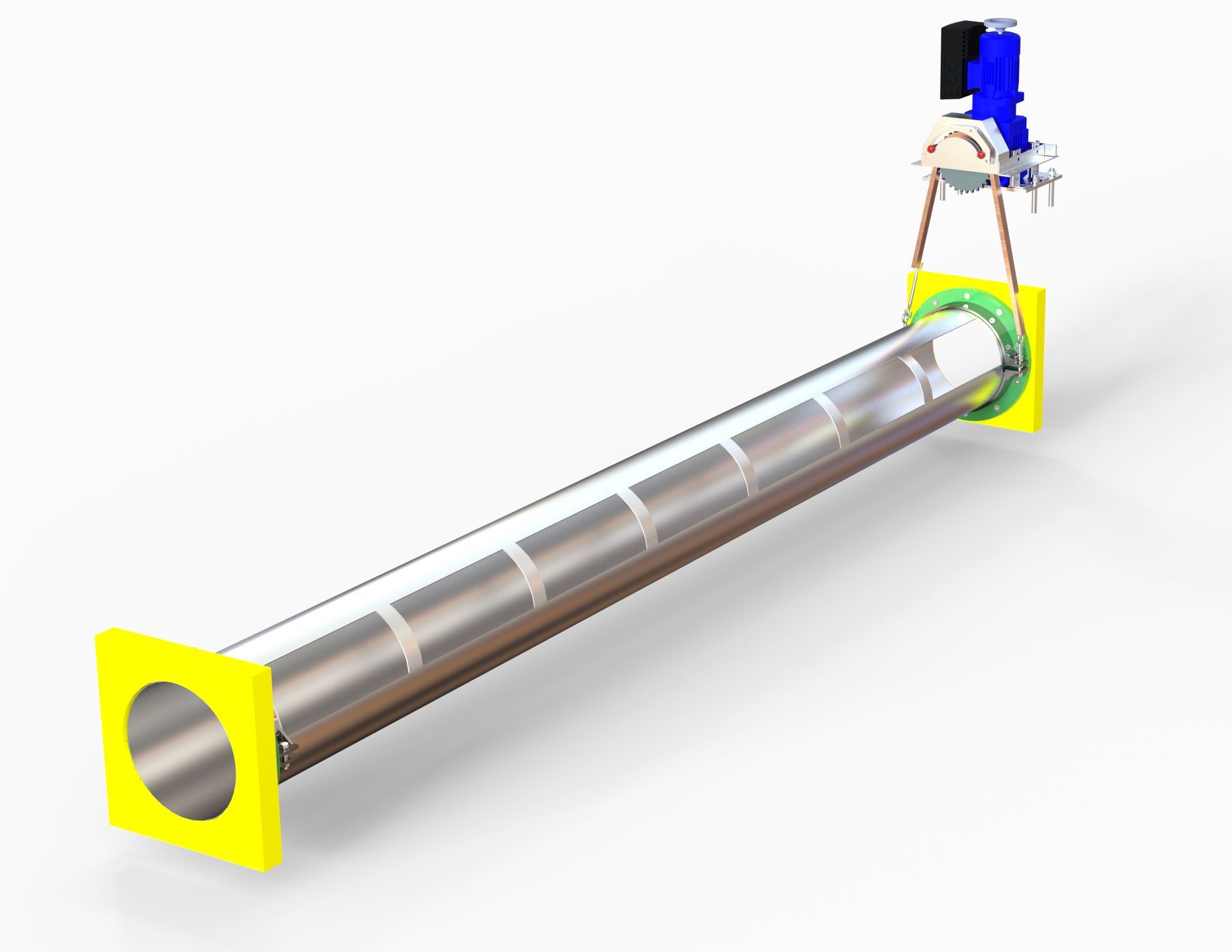

The "One Only" Merdec chain scrapers are suitable for various types of rectangular settling tanks and our components can also be used in many existing systems in the market. Our chain scrapers can be provided as top, bottom, 4-shaft, 3-shaft or multi-layer scraper systems for many types of applications such as wastewater treatment, DAF, desalination or water treatment.:

- Most Merdec Chain scraper components are suitable in almost all existing systems.

- Suitability in wide range of applications and operation conditions

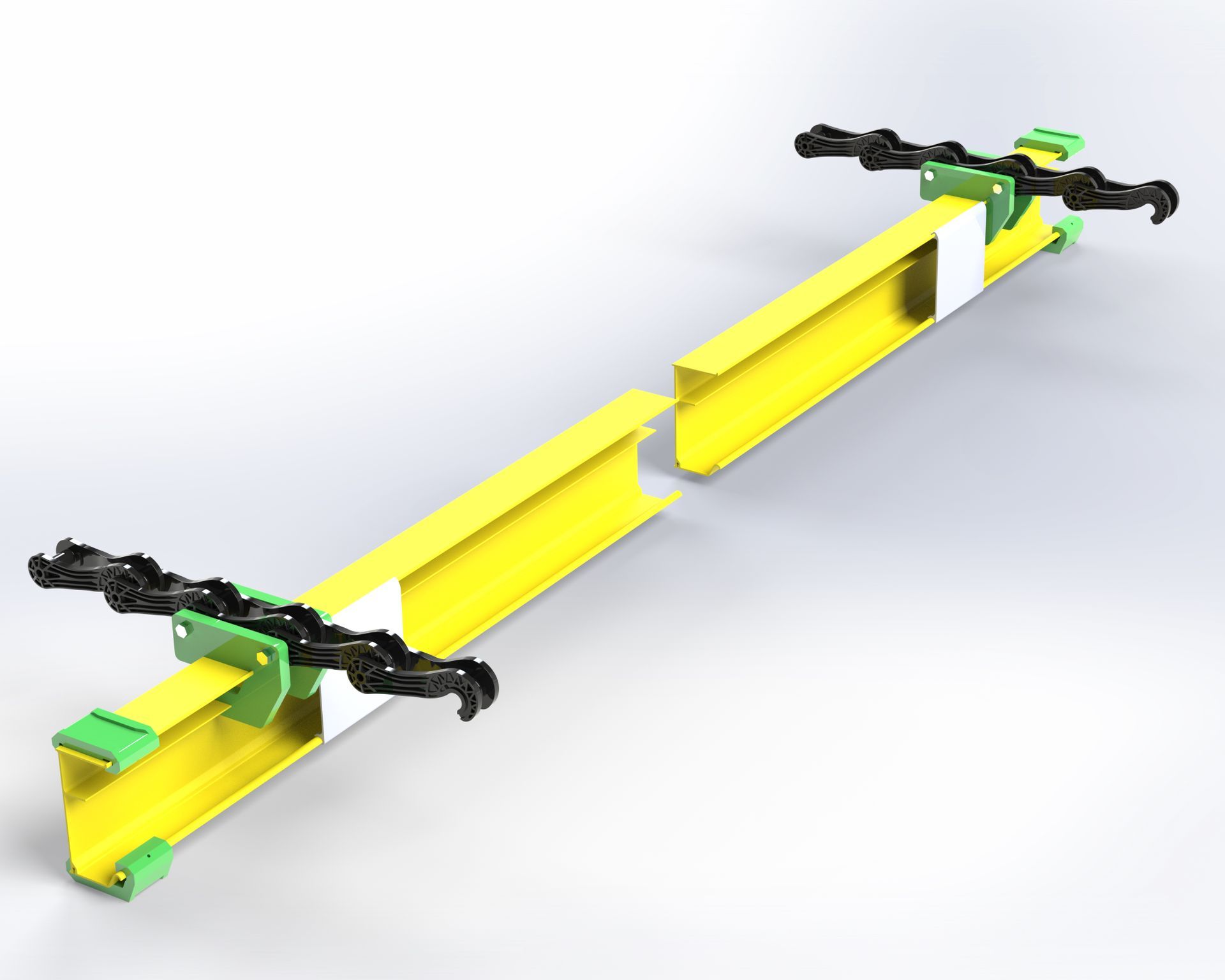

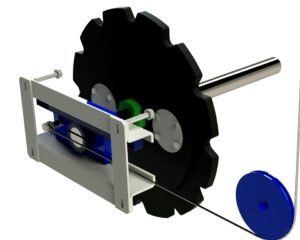

- One piece chain link and other carefully designed features ensure the system is easy to install and maintain

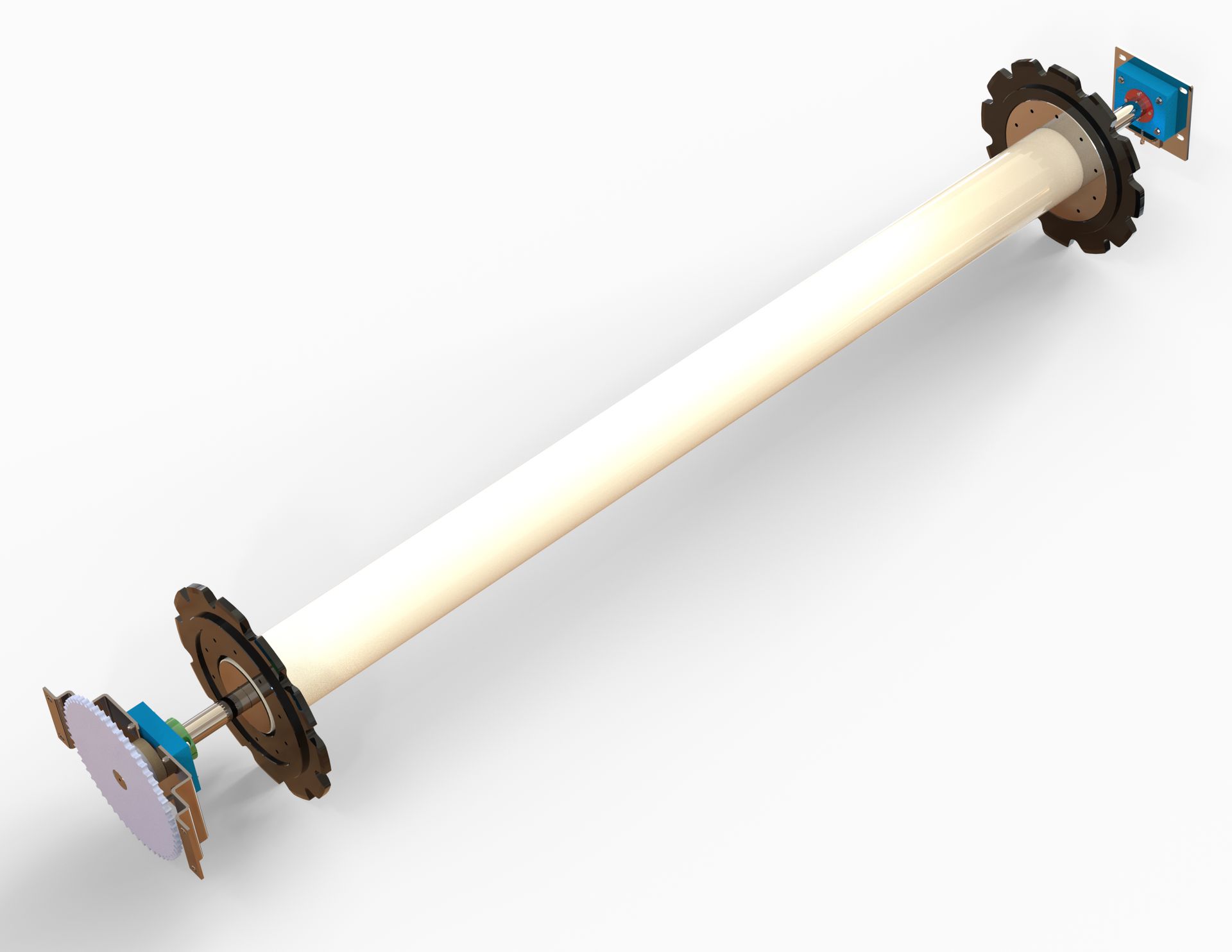

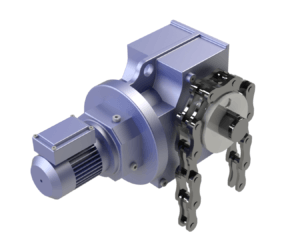

- Long service life and low operating costs (minimal water absorption, changing most of components without emptying the tank, design solutions to allow for minimal wear and tear)

- Cost-effective price structure (Quick ROI)

- High quality construction materials and components

Scraper component sales

Additionally, to complete systems, Merdec provides components for almost all existing chain scraper systems in the market whether it’s spare parts or for refurbishing. Our components are compatible with most of non-metallic Chain and Flight Collectors. We also provide and design complete systems to customers by supplying the complex parts while designing some parts for the customer to be produced locally (e.g. stainless steel shafts and rails). When heavy and bulky parts such as stainless-steel components are produced locally avoiding transfer through sea, it saves both the customers’ money and the environment!

Applications

Potable water

To remove heavy sludge (slit and mud) from the sedimentation tank requires strong and reliable sludge removal systems. We at Merdec have the capacity and know-how to do this job. Being a pioneering engineering company with vast experience in this field, .

Domestic wastewater

Merdec chain scrapers are ideal for primary and secondary settling applications where sludge loads require strong wear and tear resistance. We provide durable solutions for wide and long as well as multi-deck sedimentation tanks.

Industrial wastewater

Merdec chain scrapers are applicable in various industrial wastewater applications, such as API, Desalination, Pulp & Paper etc. as well as grit and grease chambers. Our components are supplied according to the many material standards required by each application..

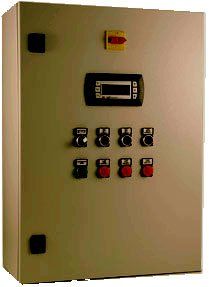

System Components